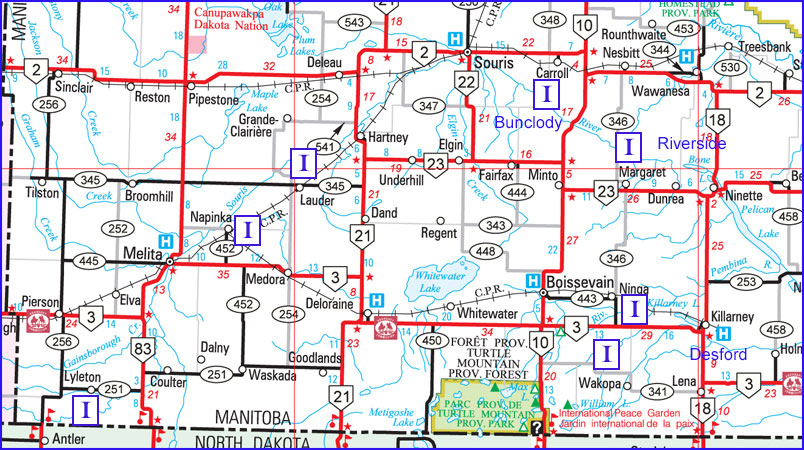

Lime Kilns

| Some years ago, while walking

along the high riverbank overlooking the Souris River near Bunclody, I

found what appeared to be an old well lined with fieldstones. I gave it

little thought until I learned about the small lime kilns that settlers

often constructed to make mortar for the many stone buildings that dot

the southwestern corner. They are another example of small, local, do-it yourself, prairie enterprises.  The remains of a kiln, near Bunclody Early settlers used it to purify and freshen damp basements, in the henhouse, in cement and plaster and for whitewashing walls and ceilings. Part of the spring housecleaning ritual was the whitewashing of the interior of the little building with the half moon cut in the door. The only "accessory" in that little building was a nail and string to hold the previous year's Eaton's catalogue, which was used to the very last page. Locations  Angus McRuer describes one located near his Desford-area farm… “This kiln was on a rise of land sloped to the north. A hole eight feet deep by ten feet across was made at the top of the slope. A trench three feet wide by thirty feet long was dug, starting at the bottom of the hill, up into the bottom of the big hole. It was like a big clay pipe. The trench acted as a damper.” To prepare for a burn, stones were placed in the kiln leaving an arch at the bottom to hold the fire. The process took three days to reduce the limestone to powder. In addition to using it for making mortar, people used it to purify and freshen damp basements, and in cement and plaster and for whitewashing walls and ceilings. There were several of these small local enterprises in our region. Many are small and barely recognizable. They are usually on the side of a creek bed or hill to allow access to one side of the kiln to feed the fire and to provide the necessary draft to create a hot and steady burn. Like so many of these local initiatives, with the improved train service, the availability of a reliable and ready source of products in the local lumberyard saved local builders a lot of time. Most kilns had ceased operations by about 1900. |