|

Emerson

In 1876

a steam grist mill, with two run of stone, was built in Emerson by Mr.

Charles Borrow. Press reports indicate that the HBC renovated a large

Flour Mill in 1884 . At various times a mill called the Stauffer Mill,

and ones owned by Fraser & Co. and Pocock & Sons were in

business.

In 1881

Messrs. Carney & Watson built a sawmill which had the capacity of

turning out 25,000 feet of lumber per day, using hard wood taken from

their own timber, located on the Red River, a few miles south of

town.

Noble

and Follis manufactured common lumber, doors, sash, blinds. Their

factory was located on Main Street, and consisted of one building 24x54

feet in area, with two flats; also an, addition of 16x50 feet. They

employed about twenty-five hands.

Edward

Sabin & Co. were general carriage, sleigh and cutter

manufacturers. In connection with their manufacturing they

conducted a general blacksmithing, shoeing and repair shop.

Press

Clips

S:

Commercial, September 4, 1883, p. 413.

“The Hudson Bay Company have

decided to reopen their large flour mill here. Water is to be supplied

the mill from a drain from the river up which water will be forced by

windmill power. A warehouse with a capacity of 12,000 bushels is to be

built alongside the mill. The company will also build a 20,000 bushel

elevator at the station.”

S:

Nwfmm, October 1883, p. 254.

“The HBC are building a large grain

storehouse next to their mill at West Emerson.”

S: AM,

January 1, 1884, p. 28.

“The addition to the Hudson Bay Company’s mill

at Emerson, Manitoba, is nearly completed. It is proposed to convey the

water supply from the Red River by means of a trench to a reservoir

beneath the mill.”

S:

Commercial, July 8, 1884, p. 805.

“The Emerson steam grist mill

commonly known as Stuaffer’s Mill, was sold on the 2nd inst., under a

foreclosure of mortgage, and was purchased by Mr. Curran for $4,220. It

will be put in operation of Monday the 7th.”

S: AM,

August 1, 1884, p. 430.

- “Stauffer’s Mill”, at Emerson, Manitoba, was

sold July 2 under a foreclosure of the mortgage. It was purchased by

Mr. Curan for $4,220. It was put in operation July 7.”

S: AM,

April 1, 1885, p. 194.

“At Emerson, Manitoba, on Mach 30, James Watson

was killed by the bursting of the fly-wheel of a grain crusher, and Mr.

Van Wert was wounded in the arm.”

S:

Nwfm, January 1892, p. 24.

“Fraser and Company’s grist mill at Emerson,

Manitoba is running to its fullest capacity.”

S:

Commercial, 8th Annual Supplement, p. 634.

- Owner: Fraser and Company

with 300 barrel day capacity.

S:

CMGE, March 1910, p. 75.

- “The German Milling Company has bought

Pocock and Son’s mill at Emerson, Manitoba.”

West Lynne

West

Lynne Charter for the incorporation of West Lynne was granted in l882.

The town was laid out twenty four blocks long and three and one half

blocks wide.

West

Lynne boasted of four general stores; six hotels and a brewery, where a

six quart pail could be purchased for fifteen cents. They also had a pop

factory and a cheese factory.

Press

reports indicate several flour mills operated for a time.

Press

Clips

S:

HBCA, D.20/16 – 1880.

- J. Ogden Grahame to J.A. Grahame, May 5, 1880,

fo. 139 – mentions memo regarding new mill to be built there.

- C.J.

Brydges to J.A. Grahame, May 6, 1880, fo. 141 – regarding erecting mill

and granary: "I am satisfied it is better than letting anyone else do

it and it will materially help your store and the place and

surroundings generally."

- J.H. McTavish to J.A. Grahame, July 5, 1880,

fo. 441 – laid out sites for mill and granary at West Lynne: "the same

as those chosen by yourself ;" Kenway received only 1 tender for $5,000

which shouldn't be accepted until estimate made."

S:

HBCA, D.20/23 – 1882

Ronald McLaren (St. Boniface) to J.A. Grahame,

June 15, 1882, fo. 144

- offer to move "flouring mill" at West Lynne

and Erect same on a new site about 300 feet from its present position

as specified in advertisement;" 20 feet addition to end of building;

new engine room; sink well; for $8,860.00.

- fo. 149 – copy of call for

tenders

Charles Esplin to J.A. Grahame, June 17, 1882, fos. 150-155 –

tender

- D. Matheson (W.L.) to J.A. Grahame, June 20, 1882, fo. 164 –

Emerson mill offering 95 cents per bushel; Ogilvie Company paid $1 for

2000 bushels delivered at Emerson station.

S:

HBCA, D. 20/25 – 1883

D. Matheson to J.A. Grahame, January 5, 1883,

fos. 6 and 6d

- This fall when the mill was being re-erected I had two

wells sunk to the depths of 24 and 30 feet, getting water in both cases

at 12 feet but not in sufficient quantity to run the mill and I have

not the means of going deeper. A supply could have been brought from

the River at an expense (before frost set in) of $700.00, but as you

were absent I did not feel at liberty of going to the expense."

- mill

is idle; feels bad grain would prevent profitability in any case; "and

now that grains are being run on the Pembina Mountain Branch of the

C.P.R. all the Western grain hitherto sold here, will be marked at

Smuggler's Point and other stations along the line."

S: G.F.

Tennant (Mayor, West Lynne) to J.A. Grahame, March 20, 1883, fos.

266-267 - urges Company to operate mill or leave it; present mill

prevents others from operating

S:

HBCA, D. 20/31, 1884.

D. Matheson to J. Wrigley, November 10, 1884, fo.

24 – took possession of mill on a "landlord's warrant"; to be put up

for sale; engineer wishes lease transferred to him, "but he thinks the

conditions are too exacting and the rent too high."

"It is

reported that the Hudson's Bay Company's mill, at West Lynne, will be

remodelled to the roller system."

Manitou &

Manitoba City

Manitoba

City

Manitoba

City was yet another ambitiously named community. By 1883 it had become

a roaring town with six licensed hotels, two liquor stores, five livery

stables, three lumber yards, a Medical Hall which housed the drug store

but also held offices for out of town doctors and other businessmen to

set up appointments, an undertaker, and numerous grocery, hardware and

implement outlets. Seven Justices of the Peace were appointed in an

attempt to keep the boom town under control.

Alas

a bit of a turf war, worthy of a modern industrial intrigue movie,

ended with Manitoba City giving way to its rival Manitou – a competing

village located just on the other side of the new railway line.

The

story, involving, land speculators, sharp lawyers, crooked CPR

managers, and a general assortment of shady deals, is well told on

several of the Manitou local histories.

Like

quite a few boomtowns – it had a grist mill – but the life of the town,

and thus the mill, was short.

Manitou

In 1881

John McIntosh started a small mill at Norquay, north of Swan Lake and

in 1893 moved the mill to Manitou as Manitou Roller Mills.

The

building was a black, two story, box-shaped structure. On the second

floor were a track and push-car and a storeroom. The bags of feed and

flour were placed on the moved to the chute on the south side o f the

building. The customer's vehicle backed under the chute and the bags

slid down.

The

local newspaper reported: “Any institution that is a means of drawing

trade to a town is of necessity an important factor in the prosperity

of that town.“

Business

from a wider radius gravitated to Manitou. Farmers could deliver wheat

to the mill, drop milk off at the cheese factory, exchange eggs and

butter for groceries at the store of their choice, have a square meal

at the hotel for a few cents, spend an afternoon catching up on news

around the stove at the livery barn, then late in the day pick up flour

ground from their own grain. They usually took home the bran and shorts

to be made into mash for the livestock. Screenings from the cleaner

provided fuel for the mill along with cordwood brought in exchange for

milling services. Often no money needed to change hands.

Revisions

included a new seventy horsepower boiler, all that was needed to keep

the mill up to date.

An ad

from 1899 stated: Manitou Mills - Grinding done promptly, Chopping on

Wednesdays and Saturdays. Best Hungarian Flour - $1.80. Best Strong

Bakers Flour - $1.60.

A Mr.

Whiteford operated it until the early 1920's when it was closed.

This

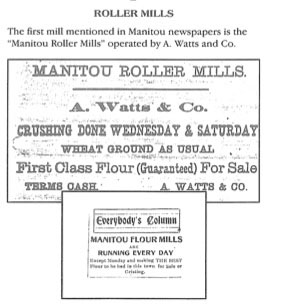

ad appeared in the Manitou paper in 1885. We don’t know if John

McIntosh bought it, or whether it had already ceased operation. Either

way, the name lived on

This

ad appeared in the Manitou paper in 1885. We don’t know if John

McIntosh bought it, or whether it had already ceased operation. Either

way, the name lived on

Darlingford

Along

the old Boundary Trail, at a point just west of Calf Mountain,

there was a conveniently flat spot on the Little Pembina that made a

good crossing. As often happened at crossings, a small village sprang

up. This one was called Darlingford. Like so many other villages it

started at one spot and re-started at another when the railway arrived.

In the meantime it served the needs of travellers and settlers,

providing some necessities. Along with stores, stopping places

and a post office, there was a saw and grist mill was run by thye

Findlay Brothers.

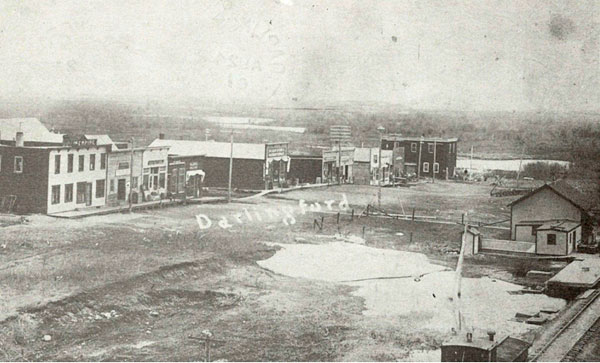

Darlingford

1909

Darlingford

1909

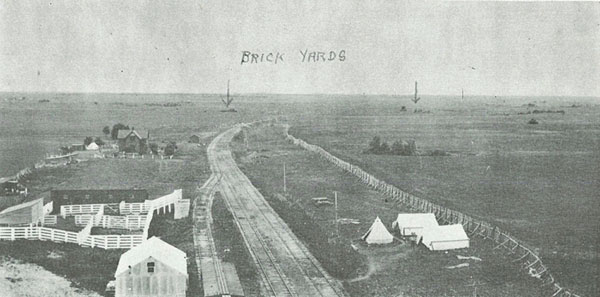

The new

site of Darlingford grew quickly along the railway line. Along

with the usual stores and services there were two brickyards. About

1898 Whalen’s Brick & Tile operated just west of the village. It

must have been quite an operation for the CPR ran a spur out to the

site, and he employed about ten people for a time. Although the bricks

were of a good quality, the operation didn’t last.

A photo shows the brickyard location.

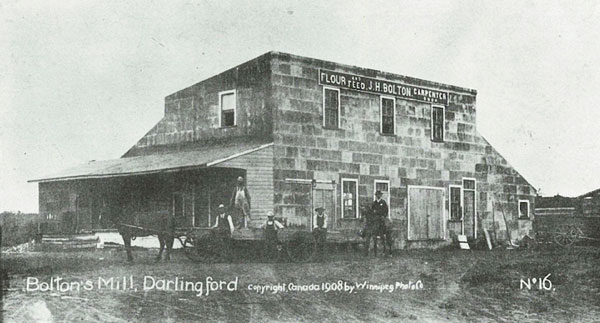

Bolton’s Mill

S:

Nwfmm, Special Ed., 1883, p. 20.

“Darlingford, one of the rising

towns on the south-western railway, is to have a $100,000 company to

erect an elevator, mill, and warehouse. The elevator will have a

capacity of 50,000 bushels, while the mill will be similar to that of

the Assiniboia Milling Company at Portage la Prairie.”

S: AM,

October 1, 1884, p. 543.

“The grist mill at Darlingford,

Manitoba, at present under the management of H.N. Fleming, has been

purchased by Joseph Ritchie, of Nelson, Manitoba, who will put it in

thorough working order.”

S: AM,

June 1, 1885, p. ____.

“The burr mill now at Darlingford,

Manitoba is about to be removed to Morden, Manitoba.”

S: The

Darlingford Saga, p. 24.

“There were a number of business places

a saw mill and grist mill was run by Findlay brothers. Circa 1875-1882

in Old Darlingford.”

S: CH,

Darlingford, p. 39.

- Photo 1908 of Bolton’s Mill with

commentary; burned May 1912.

Morden,

Winkler & Altona

Morden,

Winkler and Altona were railway towns, part of the second wave of

community building. As such, the emphasis on gristmills, cheese

factories, brickyards and sawmills was not as pronounced. From the

start they had links to supplies and to market that made these local

enterprises less of a priority. While gristmills did thrive in

these larger communities, they did so on the basis of commercial

viability, not in terms of essentials for subsistence. Of course a time

went on other industries, more associated with modern and urban

communities, did thrive.

Their

respective histories are well documented and we will present here a

sketch of the early operations that did exist.

Morden

The

first mention of a mill comes in when Anderson and McLean accepted the

bonus offered by the district and to erect a mill. In August of

1885 we learn that Ritchie and Lundy’s had completed a flour mill and

had it in in full operation.

In 1886

James H. Fraser, the proprietor of the Nelson flour mills, decided to

erect a roller mill in Morden. Mr. James Pye superintended the starting

of the machinery in December.

Mr.

A.E. Hughes, formerly with the Hudson’s Bay Company, Winnipeg,

Manitoba, was the head miller.

The Morden Flour Mill, built in 1900

MacGregor’s

brickyard was south of Morden and its products were used to erect

several substantial brick buildings, including the Dominion Post Office.

Press Items

S:

Nwfmm, February 1884, p. 36.

“We understand that Messrs. Anderson and

McLean, two practical men, have accepted the bonus offered by the

district and will erect a mill at that point, which will have three run

of stones and four sets of rollers.”

S: Commercial, August 11, 1885, p. 905.

“Ritchie and Lundy’s flour

mills, at Morden, has been completed and is now in full operation.

S: Nwfmm, January 1886, p. 355.

“Mr. James H. Fraser, the proprietor of

the Nelson flour mills, decided last summer to erect a first-class

roller mill in Morden, Manitoba, and for that purpose contracted with

the Pray Manufacturing Company of Minneapolis, Minnesota, for a

complete outfit for a mill of 75 barrels capacity, and in the mill as

completed, this well known firm have more than sustained their

reputation as builders offirst class mills. Mr. James Pye superintended

the starting of the machinery on the 17th December. Everything moved

off in a smooth and satisfactory manner.”

The

mill will be run to its full capacity night and day, there being a

large local and western trade for flour of all grades.

S:

Nwfmm, February 1886, p. 387.

“Mr. Ritchie, the proprietor of the stone

grist mills at Morden, Manitoba, has taken a partner. The firm is now

Ritchie and McIntyre.

S:

Nwfmm, April 1889, p. 100.

“J.H. Fraser, of Morden, Manitoba, is adding

new machinery from Minneapolis.”

Bricks

Winkler

The

“West Reserve”, established in 1876, was a treeless plain similar to

the Russian steppes from which the Mennonite settlers came. These

settlers established themselves in small villages of twenty to thirty

families. In December of 1882 the Canadian Pacific Railroad line from

Winnipeg to Manitou, created the town of Winkler.

Dyck

and Peters built the Winkler Grist Mill. I find no records of the fate

of that mill, but it seems likely that the Winkler Roller Mills

replaced that service.

Judging

by the several photos in “Winkler, A Proud Heritage”, it existed for

decades.

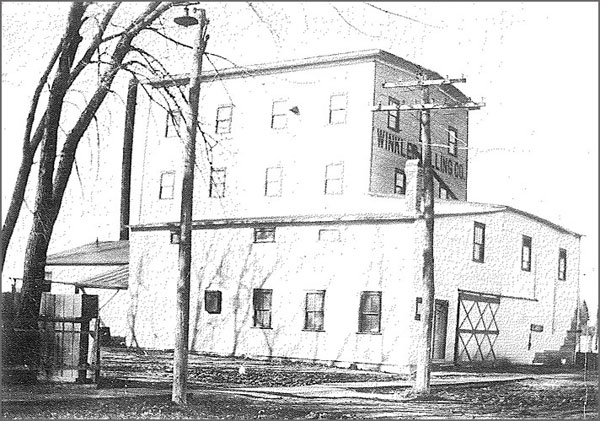

The

mill in Winkler

The

mill in Winkler

Press

Clips

S: CH,

Winkler: A Proud Heritage, 1982, Friesen, p. 78.

- 5 photos of Winkler

Milling Company Limited: 1) 1933 and 2) 1946 with the three others not

dated.

Altona

The

mills don’t play a big role in the Local History volumes of Altona but

they are mentioned.

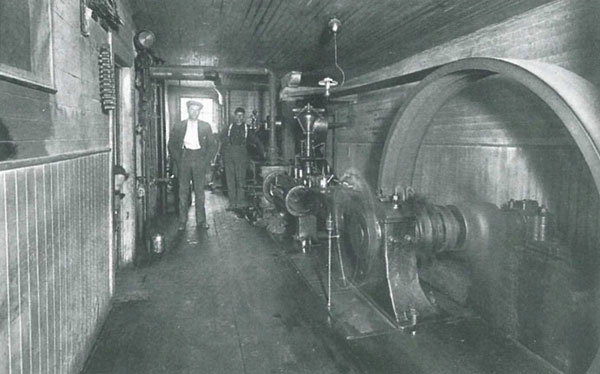

Mill

owners Isaac and David Fehr in the ”machine room”, which housed a steam

engine and this large pulley which drove the mill’s various cleaning,

grinding, and other machinery.

Mill

owners Isaac and David Fehr in the ”machine room”, which housed a steam

engine and this large pulley which drove the mill’s various cleaning,

grinding, and other machinery.

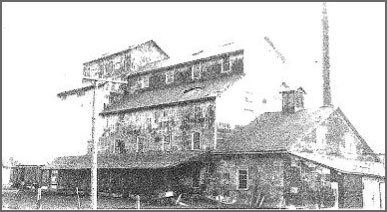

The

Altona mill in its heyday in the 1905 was the town’s main industry.

This photo shows the mill built by Peter Braun before the turn of the

century, when it was owned by David and Isaac Fehr, after the large

three-storey addition had been built.

The

Altona mill in its heyday in the 1905 was the town’s main industry.

This photo shows the mill built by Peter Braun before the turn of the

century, when it was owned by David and Isaac Fehr, after the large

three-storey addition had been built.

Friesen

Flour Mill around 1900. Owned then by Jacob. P. Friesen

Friesen

Flour Mill around 1900. Owned then by Jacob. P. Friesen

La Riviere

La Riviere

The La

Riviere townsite was laid out in 1886. It became a divisional point for

the railway, so had a roundhouse and water tank.

A flour

mill was started by Cary and Grant, burned. J. Rockett built a cheese

factory beside Mary Jane Creek.

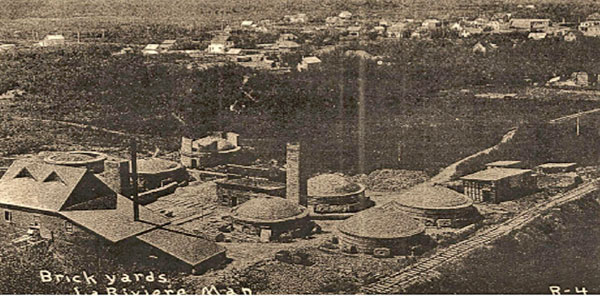

About

1902 a brickyard was established with a payroll of about thirty men,

including W. Carmichael as manager. He was followed by G.W. Dellar.

La

Riviere Press Brick & Tile Company

Adapted

from:

A

History of Brick Manufacturing in Manitoba 1860-1990

David

Butterfield 2018, Heritage Manitoba

In

1902, when tests made on local clay and shale deposits proved positive,

and the Press Brick & Tile Company, Ltd., owned by Elisha Frederick

Hutchings was established just to the east of town. A manager was found

in Minneapolis in May, and by the following month local workers were

being hired. By July, men had installed a brickyard dam, and a railway

spur to the site was nearly complete.

Early

in September the plant made its first bricks and was running “full

blast” by mid-month, with a kiln of 250,000 bricks being burned and

another 250,000 awaiting the fires. The following season (1903) saw the

firm invest $10,000 in erecting four new beehive kilns and other

improvements. Eleven cars of machinery were ordered, including an

engine, numerous castings, a blower, 100 dryer cars, and other

equipment. By late May the kilns were nearly complete, including an

arched subterranean passage linking all four. The large dryer with its

numerous brick divisional walls only lacked a roof at the time, but had

a 40-foot high stack.

Four

more kilns were under construction by mid-June. During mid-July, shale

was being taken from the hillside source by night blasting, and then

put on a carrier that took it down to the crusher where it was

pulverized into clay. Reports from the spring of 1905 show most of the

old employees back at work, and improvements included a remodeling of

the oldest kilns and the construction of a “lofty and strong” trestle

from the mill across the creek to the shale ledge.

In

January 1905, a number of men were at work at the brickyard, sorting

out and shipping the one million bricks on hand at the plant in

preparation for the coming season. But something had happened with the

firm’s financing, and the plant was suddenly up for sale . William

Brydon acquired control, and the next six years of the plant’s

operations are somewhat shadowy. In 1910 samples of brick “of a

beautiful colour and finish” were on display locally, and an

advertisement in July 1910 showed that the plant had acquired a new

manager— James Johnstone—as well as a new name: The Phoenix

Brick-works. In April 1911 it was noted that the plant machinery was

being fitted up, and a kiln was filled; given that there were at least

eight kilns, this appears to be a modest production schedule. It is not

clear if the plant was in operation in 1912, but it was sold in 1913,

to a Mr. Martin, who intended to renovate the complex, install new

machinery, and place it on a sound footing. But that did not occur, and

the plant was abandoned by 1914, as so many Manitoba plants were with

the oncoming war.

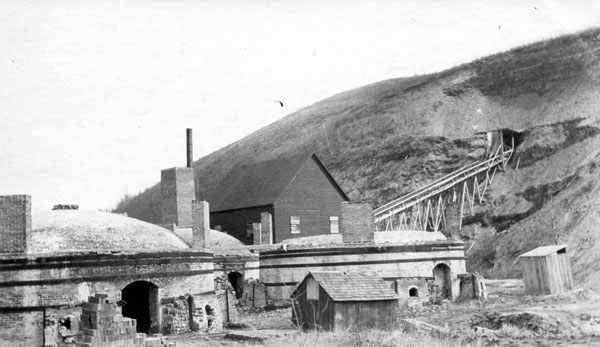

A view,

ca. 1903, looking west showing the mixing and pressing building on the

left and the kilns of La Riviere’s Press Brick & Tile Company.

(Courtesy Turning Leaves. A History of La Riviere and District,

frontispiece)

A view,

ca. 1903, looking west showing the mixing and pressing building on the

left and the kilns of La Riviere’s Press Brick & Tile Company.

(Courtesy Turning Leaves. A History of La Riviere and District,

frontispiece)

The La Riviere Brickworks, seen here ion 1907, was a large

operation involving a substantial investment in infrastructure.

The

shale deposits

on the hillside were drawn by rail cars down to the mixing and

brick-pressing building and then burned in one of the eight beehive

kilns. (Courtesy Archives of Manitoba)

Killarney

Killarney

S: Commercial, 1893, p. 634.

“At Killarney, on the Deloraine Branch, a

new mill of 100 barrels capacity, has recently been put in operation by

Young Brothers and Buck.”

S: MFP,

Saturday, April 18, 1903, p. 18.

“Young and Buck, Millers. One

of the most important institutions in an agricultural country is the

flour or grist mill. The town of Killarney is fortunate in possessing

one of the best country mills in the province. The mill, which is a

full roller process one, was erected in 1892. The leading brands of

flour turned out are Peerless, Comfort and Strong Bakers, and these

have established for themselves a reputation as high-class products

throughout the district. The surplus stock is shipped to distant

points. The firm also does a large business in chopped feed, bran,

shorts, etc., and shipping wheat and other grain. Young and Black are

regarded as one of the solid concerns of the province.”

- Mr. T.H. Buck

– moved from Boissevain in 1892 “where he was engaged in milling and

farming.”

Holmfield

The Harrison Mill has been preserved, and in 1991, was the

only fully operational roller mill remaining from the 1890s still

intact, in Western Canada.

The

Harrison Mill, prominent on the skyline of the small village of

Holmfield.

The

Harrison Mill, prominent on the skyline of the small village of

Holmfield.

Plans

for a flour mill in the emerging village of Holmfield were first

considered in the spring of 1897, when the village council approved a

by-law granting a bonus of $2,000 for the construction of a mill at

Holmfield. Brothers, William and George Harrison would build and

operate the mill.

Unlike

other mills built during this time, the Council committee in charge of

raising money for the $2,000 bonus had little trouble raising the

capital.

From

the outset, the mill was not burdened with the handicap of an operating

deficit, which might have hampered its chances of survival.

Instead, Harrison’s mill operated on a sound financial footing, thanks

to the support of the local patrons and the commitment to the

district’s farmers by the Harrison family.

In

August of 1897, the frame of the mill was raised and the stonework had

commenced.

Mr.

C.W. Avery of Toronto was hired by the Harrisons to install the milling

machinery. The engine in the elevator was connected to the boiler in

the mill so that one firebox would run the whole plant. Mr. Avery

completed this work by December 1897 and the mill began operations

either in the same month or in early 1898. As part of the

building program, the Harrison brothers constructed three new

warehouses in 1899.

The

mill was a booming business during its early years of operation.

A 1901 observer noted, “Harrison Bros. are kept busy with the mill day

and night to fill orders for car loads of flour.” Renovations

during the following year, including completion of the stonework on the

engine house and the erection of a new smoke stack. Also, the

mill’s power was boosted with the addition of a second boiler, and a

new gangway was guilt to the entrance of their elevator.

Harrison’s Mill was the site of a spectacular robbery

attempt during the spring of 1905. Thieves forced their way into

the office and blew up the big safe. The work was evidently done by

professionals. Fortunately all of the money in the safe had been

removed the night before and the thieves received nothing for their

pains. No one was ever caught.

Like

all rural mills, it experienced a major surge in business during the

Depression, and some renovations were undertaken in 1934. The

steam power plant was replaced by a diesel engine and “new elevating

and flour tubing” was installed. With the exception of the substitution

of electric power for diesel in 1947, no other major changes in the

milling equipment have been undertaken at the mill since 1934.

During

the evening of July 26, 1934, a fire, which was confined to the roof of

the east wing, was put out after about an hour. It had originated

from overheating in a box above the boilers. Thanks to a favourable

wind direction and the yeoman efforts of the bucket brigade, the mill

was saved.

During

the 1930s the mill worked at maximum production. In exchange for

the continued benefits of high quality, locally-produced flour and the

production of by-product livestock feed, the residents of the district

agreed to pay four bushels of wheat for one hundred pounds of flour, in

lieu of cash. This informal arrangement was put into practice

because the owners were deeply committed to the welfare of the

district. As residents of the district, the Harrison brothers

operated their mill during tough economic times largely as a public

service to the people of the district. The farmers fulfilled

their end of the bargain by paying amounts owed. Storage facilities in

the Harrison Elevator made it possible for the mill owners to buy grain

at low prices and hold it for later milling a practice utilized by

large milling firms.

During

World War II, flour mills both big and small across North America were

pressed into action with a mandate to produce flour for the Allied

troops and civilians needing scarce foodstuffs. At its peak

during World War II, the Harrison Mill produced about 50,000 bags of

flour. During the early 1950s, overseas contracts were available while

the European economy and landscape were under reconstruction.

Harrisons shipped 4,000 bags of flour overseas in 1951. The

overseas market slowly disappeared as Europe recovered and the Wheat

Board denied small milling firms the wheat needed to operate.

During

the 1960s, 70s, 80s, and into the 90s, the mill gradually scaled down

its operations to concentrate on a purely local market. The flour was

distributed locally under the brand name “Turtle Mountain Maid” and

available for purchase in local retain outlets.

Interior view of the mill showing part of the elaborate drive system.

(Harrison Family Photo)

The mill, shortly after construction, ca. 1897. (Harrison Family Photo)

|