|

Railway

Towns

/ Hartney & Area

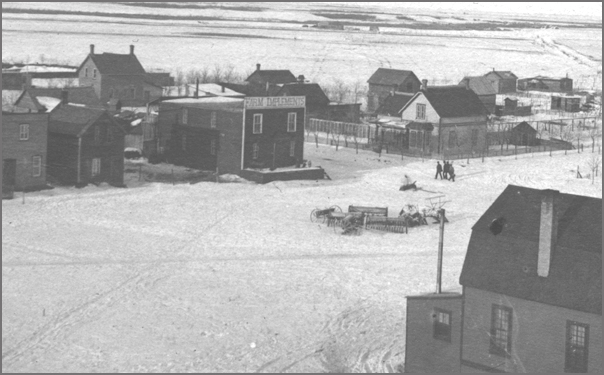

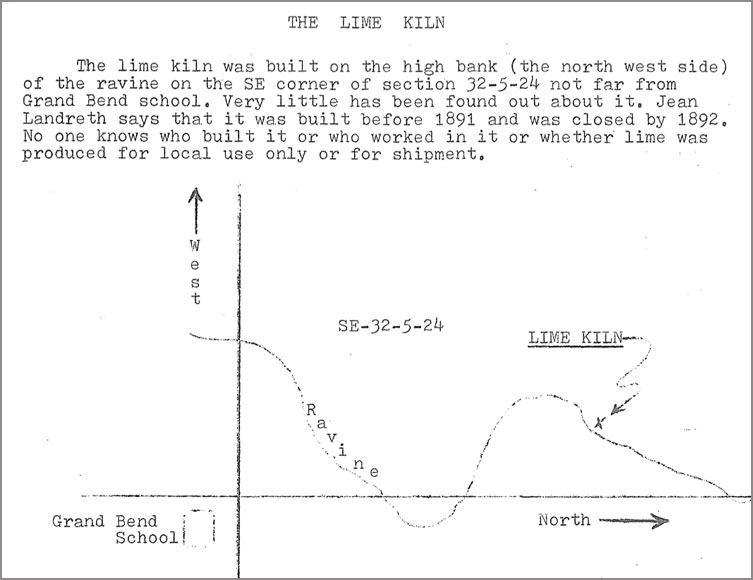

The Flour Mill Hammond and Leckie, who operated a successful lumber yard and grain elevator in Hartney, entered the flour milling business. A substantial structure was erected, machinery installed and by 1894 it was in full operation. Coal from Estevan and water drawn by tank from the river, provided the steampower. In 1896 the company they hires James Innes as miller. A pipeline to the river made the supply of water more easily obtainable. The mill produced high-grade flour and was a boon to the community. It purchased wheat locally as well as shipments from other areas. It attracted workers who made their homes in town and contributed to its life. 1n 1902 Innes and Frank Hill purchased the mill. They developed an overseas market for their flour and in 1905 selling their product as far away as Britain. Through James Innes' efforts a marketing agency was established for nineteen of Manitoba's mills which became "The Canadian Consolidated Flour Mills". Mr. Innes went to Glasgow to promote sales. Business prospects were bright.  Photo from the Grassland Collection All went well until 1907 when a Chicago grain merchant cornered the market. The western grain firms, including the Hartney Milling Co., had bought grain for delivery and found themselves short of funds to cover the purchases. The Union Bank, alarmed, gave Innes a few hours to pay off his grain loans. He had grain in storage but could neither sell the grain nor raise the necessary funds. The Bank seized the mill. It was closed in September, while the Hartney Board of Trade tried to find a solution and get the mill back in operation. They formed a Joint Stock Company to buy the mill from the Union Bank with a provisional Board providing funds. By May 1908 the "Hartney Flour Milling Company" was formed. They offered the Union Bank $15,000 for the mill property. The Bank asked $18,000. No agreement could be made. The company then offered to rent the mill property from the Bank and hire a manager to operate it. The Bank refused to rent and the mill remained closed. James Innes found a position with another milling company and when, in 1912, no progress was made, he sold his home and moved his family to Brandon. Later the milling machinery was sold; the building torn down, leaving no trace in the town of the activity that held so much hope at the century's beginning. Bricks The most extensive brick-making operations in the southwest corner were located in Hartney. The reason may lie partly in the quality and quantity of the clay deposits, but the dynamics of the community and the perseverance of some local entrepreneurs were also factors. In any case it was important in Hartney and it involved three enterprises. The most important operation was that of William Kirkland, who was actually the third individual to develop a brick operation near Hartney. From what we know he was certainly a typical businessman of the era: a hands-on industrialist with real skills and craftsmanship. At the height of his ten years of brick-making, in 1913, he was firing 10 million bricks for the new Saskatchewan Legislative Building. That contact alone likely brought in at least $80,000. He was able to build a grand house at the north end of town, with a prominent and stately view into the community. Brick, of course.  The Irene Hill house in Hartney was built by Harry Payne using bricks from his local brickyard. Harry Payne was the first to make bricks in Hartney. He began in 1895, just west of town. Payne sold bricks to W. Hopkins for his new store, and was also shipping to many other places in southwest Manitoba. Payne’s reddish bricks were used in many local buildings, but by 1902 the operation was gone, either having depleted the clay bed or succumbing to the local competition. He had made at least 3,500,000 bricks. George Sackville opened his operation in 1898, and called it the Hartney Brick and Delft Company. Located east of town, the operation produced what was called a white brick (actually more of a buff colour). Sackville continued for three years to ship brick over the Northern Pacific and Manitoba Railway line to points throughout southern Manitoba. William Kirkland, who had worked for Sackville since 1899, took over that yard in 1901. Kirkland`s first kiln of 80,000 bricks went into the new A.E. Hill and Company building then under construction. In May of 1905 the Star commented on the “fine and inexhaustible deposit of clay” that was being worked by Kirkland’s steam brick machine. The yard sat on 15 acres and produced 30,000 bricks per day, with 10 men employed. The three Hartney operations—Payne’s, Sackville’s and Kirkland’s—describe the typical range of brick operations in rural and small-town Manitoba, with the Payne and Sackville yards on the small side and the Kirkland operation (the successor to Sackville) on the larger side. The Lauder Cheese Factory In May of 1892 a meeting of ratepayers took place to vote on the issue of bonds to raise money to assist the establishment of a mill in Lauder. In 1893 an agreement was signed between the Municipality of Winchester and Giddens and Campbell of the London Engine Supply Company. This agreement called for a fifty-barrel mill that was to run full time and be operational by September 15, 1893. By mid September the second story was up but work did not progress as fast as planned. It was in operation part of the time in December but was having trouble getting enough water for the steam engine. The mill was not fully completed until January 1894. On April 6, 1894 another new agreement was entered into and the next day a mortgage was given to Council on the mill and running machinery. The mill was to be kept running at Lauder for five years from January 1, 1894 and to be kept in operation 10 months of each year. There were management and ownership problems that seemed to plague some rural milling operations In 1895 Messrs Morrison and Reid of Brandon bought the mill and were keeping it running almost day and night. They installed a new engine in 1896 and everything appeared to go smoothly until some time in 1897. In 1898 the owners simply left town without notice. In 1899 several carloads of machinerv from the mill left Lauder enroute to Headingly where the mill was to be re-erected. The mill site came up for tax sale a bit later. Manufacturing As towns grew, both the demand for goods and thus the possibilities for industry expanded. For a short time Hartney had both a Pump Factory and a Sash & Door Factory. The story of the pump factory illustrates both the possibilities and the limitations of local manufacturing.  The building at the centre, where the Town Hall is now located, housed Mr. Pierce’s Pump Factory On farms, water came from wells. Wells required pumps. Everyone need one…or two. So in 1893, when H. C. Pierce began making pumps, he quickly supplied one thousand pumps for the local market. But soon everyone had a pump, and business slowed down pretty quickly. On the other hand, when Alex Mains, and his brother set up a Sash and Door Factory, in 1900, and added a planing mill to provide materials for the many new homes which were built in this and other communities, the need for such materials was a little more ongoing. In 1904 it became a joint stock company called "The Hartney Manufacturing Co.” and prospered until 1908 when they shifted their business toward providing lumber. In this case not only had demand slowed down, but the economics of trying to compete with large operations elsewhere destroyed the viability. The same process repeated itself as small town manufacturing gave way to big city factories, which in turn has given way to offshore production. Carriage Makers Another common example of small town manufacturing focused on another vital need was the carriage maker. Victor Duchesneau arrived in Hartney about 1901 and in 1904, along with his blacksmith business, he started a carriage and wagon factory. His advertisements at the time announced that he had "a new eight-horsepower engine, modern band-saw, a joiner, a fine ripsaw, a hawk-eye trip hammer, a fan blower and a fine grade emery polishing machine,'" and that he could turn out "buggies, wagons, carriages and all fine lumber work with city style and finish."  The Duchesneau shop – Carriage making meant working with both iron and wood. Edouard Isabey, who opened a small machine shop in about 1893, also made and repaired carriages. He had apprenticed as a gunsmith and mechanic in France. In a listing of Hartney’s early businesses we also find an entry for “Shore and Co. carriage makers.” Clothing Many Tailor Shops and Women’s Clothing retailers, did more than mere alterations and fittings. In the A.E. Hill Store in Hartney, on the upper floor could be found carpets, linoleums and the millinery and dressmaking departments. Each season a milliner and assistant came from Toronto and made hats for the spring and fall. A head dressmaker was employed, also from the east, and local girls were hired to work as apprentices. In 1894, the Edwards sisters were running a successful dressmaking shop in Hartney, offering the latest fashions, wedding gowns and party dresses, often paired with hats made by the milliner at A.E. Hill & Co. The girls had apprenticed with a dressmaker in Melita and were putting their skills to good use. Lime Kilns Near Lauder, a lime kiln was built on the high bank (the north west side) of the ravine on the SE corner of section 32-5-24 not far from Grand Bend school. It was likely in operation for a short time. Sometimes these small kilns were just used for a specific building project.  Gordon Phillips described the location of a Lauder area in “The Rise and Fall of a Prairie Town: A History of Lauder Manitoba and The Surrounding District, Volume # 1.” Like so many of these local initiatives, with the improved train service, the availability of a reliable and ready source of products in the local lumberyard saved local builders a lot of time. Most kilns had ceased operations by about 1900. Cheese Factory In 1895 the farmers of the Lauder area met to discuss the idea of a cheese factory. June 1 was set for the start of production. The factory was located just east of the village. Hobert Sibald was paying daily visits to the farmers for milk in June of 1895 The milk was gathered large barrels and the whey returned to the farmers for feeding pigs. Henderson Directory for 1897 lists W. Brigden as manager. The factory became a Saturday night gathering place for locals and several others who sat around eating cheese and soda biscuits and discussing the events of the week. It did not last for any great period of time probably not more than a year, In any case, it was gone by the summer of 1897. |

|

|

|